|

Ningbo Rellwin Industry Co.,ltd.

|

Slat Top 820 Straight running plastic chain Flat Top Belt Conveyor Flat top straight running conveyor

| Price: | 20.0 USD |

| Payment Terms: | T/T,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

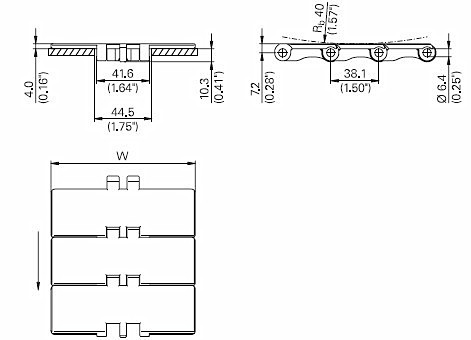

1.Thickness:4.0mm

2.Backflex Radius(min):50mm / 1.97inch

3.Material:POM

4.Weight:0.83kg /m

5.Pitch:38.1mm

6.Pin Material:Stainless Steel 304

The main application is for conveying various food products and containers.

820series is a plastic version of the related 812 steel chain. The plastic chains however

have a reinforcing middle rib underneath.

The link thickness is 4.0 mm (0.16 in.) for the 820-series.

The links overlap, so there is no space between the links.

820-K325 Flat top conveyor chains

Straight Run chains 820-K325

Thermotic TableTop Chains

820 Series conveyor chains

Max speed: 90M Iubricant(suggestion)

60M Dryness

Pin: Stainless Steel

Packing: 10feet=3.048M/box 1M≈ 26PCS

The longest distance=12M

Chain Material: POM

Chain Colour: Brown

| Chain Type | Plate Width | Working Load(max) | Backflex Radius(min) | Weight | |||

| mm | inch | N(21º C) | IBF(21º C) | mm | inch | kg/m | |

| 820-K250 | 63.5 | 2.50 | 1230 | 276 | 50 | 1.97 | 0.73 |

| 820-K325 | 82.6 | 3.25 | 1230 | 276 | 50 | 1.97 | 0.83 |

| 820-K350 | 88.9 | 3.50 | 1230 | 276 | 50 | 1.97 | 0.87 |

| 820-K400 | 101.6 | 4.00 | 1230 | 276 | 50 | 1.97 | 0.95 |

| 820-K450 | 114.3 | 4.50 | 1230 | 276 | 50 | 1.97 | 1.03 |

| 820-K600 | 152.4 | 6.00 | 1230 | 276 | 50 | 1.97 | 1.25 |

| 820-K750 | 190.5 | 7.50 | 1230 | 276 | 50 | 1.97 | 1.47 |

Plastic tabletop chains are made of engineering plastic and are connected using stainless steel pins. The plastic tabletop chains are constitute a

light-weight yet strong and slient alternative to steel chains.

These chains are used mainly in the food and packaging industry for conveying of many kinds of containers. For example: PET bottle, PET

petaloid bottle, Aluminum and steel can, Crtons, Trays, Packaged products(cartons, shrink packs), Glass, Plastic containers.

Benefits:

----Accuracy of molding proxess guarantees optimum flatness

----High wear resistance and low friction

----High working load

This kind of chains are often used for conveying cans, cartons, trays, shrink-wrapped products, glass, PET and petaloid bottles and other plastic containers.

Plastic tabletop chains are made of engineering plastic and are connected using stainless steel pins.

The plastic tabletop chains constitute a light-weight yet strong and silent alternative to steel chains.

These chains are used mainly in the food and packaging industry for conveying many kinds of containers.

For example:PET bottle,PET petaloid bottle,Aluminum and steel can, Cartons, Trays,Packaged products (cartons,shrink packs),Glass, Plastic containers.

Accuracy of molding process guarantees optimum flatness

High wear resistance and low friction

High working load

This chain offers a new and unique solution for sideflexing applications in plants with modular conveyor chains. The chainchain is best suitable for

conveying glass and PET containers(for example pet bottles with petaloid base).

BENEFITS

-high strength and heavy duty flight design.

-standardisation in conveyor design.

-optimum product stability.

These chain used in a variety of industries including manufacturing, assembly, and packaging, for example, cosmetics, foodstuffs, paper, electrical

and Electronic sectors, mechanical, chemical and automotive

Plastic modular conveyor chain ,Which comprises two U-shaped bifurcated chain precursor forked chain binding site and the body is provided with bifurcated pin hole, pin, characterized in that the chain precursor has a matching chain and independent of each other on the gland. Plastic conveyor chain has a long life, easy maintenance, wear-resistant not afraid of corrosion, the assembly can turn characteristics, and assembled without lubrication, turning flexible, with good flexibility, can be widely used in electronic , tobacco, chemicals, beverages, food, beer, daily necessities and other industries

820 conveyor chain is used for packing line, aquatic products processing production line, frozen food production lines, battery manufacturing, beverage

manufacturing industry and agricultural processing industry, chemical industry, electronics industry, viviparous rubber tire industry, cosmetics industry,

general transport operations.

Roller top 400 plastic conveyor chain material: pom (pom) PP (polypropylene), PE (polyethylene), ACETAL (ACETAL), NYLON (NYLON), and other materials.(some chain type conforms to the FDA, the USDA standards, so it is widely used in tire industry.)Structure are: straight and level transport, lifting /, transportation, and other forms of turning, conveyor chain can also add lifting, side panel, such as accessories, can meet various requirements in the form of transport.Features: use plastic material which is conform to the hygiene standards,

there is no wool stoma and aperture structure.Regardless of any product.Will not be entrained by product oil pollution by osmosis.Not any impurities on

the conveyor chain surface adsorption.So can be one of the most secure of the manufacturing process.In addition, its stability and chemical resistance

is strong, will not damage by cleaner or high temperature water.

Our services

1. Warranty time: 1 year. The conveyor belt / chains / sprockets which supplied by our company could be exchanged when it have quality problems,such as it was broken in installing , the pin run out from chains or the chains parted . But if the user use it in a wrong way, we can not provide any goods for free .

2. Payment: T/T , L/C , Western Union or Paypal .

3. Lead time: 5~15 working days, subject to the order quantity.

4. Shipment: by sea, by air,door to door service for samples transportation.

5. OEM service : we have our own R.D team . If you want to purchase the belt which we have not or you have your own design , we would like to make mold for you for free , only have the condition of requiring continuous orders ,and first order must be more than 60 square meters .

Company and Productsinformationrelated:

Ningbo Rellwin IndustryCo.,ltd.