|

Ningbo Rellwin Industry Co.,ltd.

|

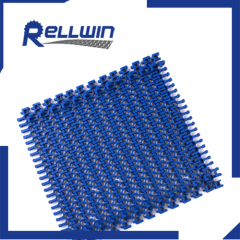

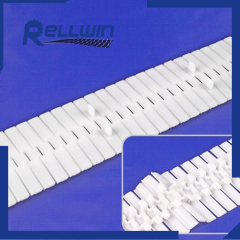

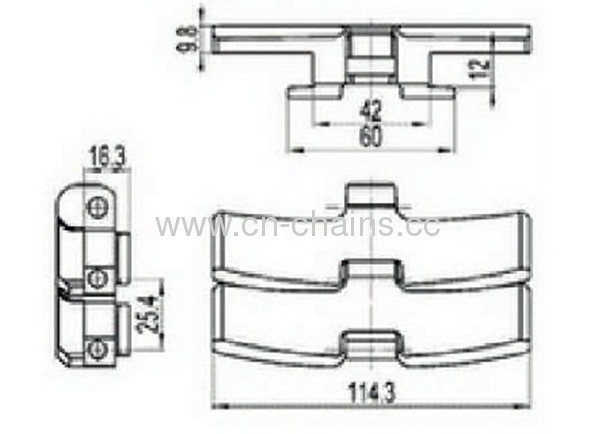

Slat top sideflex Flat Top chainbelt(50mm pitch) for machinery

| Price: | 35.0~85.0 USD |

| Payment Terms: | T/T,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to Basket | Add to My Favorites |

| HiSupplier Escrow |

Product Detail

1.Max temperature:90ºC

2.Sideflex Radius(min):457MM

3.Backflex Radius(min):50MM

4.Material:POM

5.weight:2.08kg/m

6.pitch :25.4mm

6.pitch:25.4mm

These chains used in a variety of industries including manufacturing, assembly, and packaging, for example, cosmetics, foodstuffs, paper, eletrical and Electronic sectors, mechanical, chemical and automotive industry.

Chains colour: Blue(also can be depend on customers' requirement)

Material: POM

Pin: Stainless Steel

Max temperature: 90º C

Flat top plastic modular sideflex chainbelt design

Flat Top spiral CHAINBELT

Sprockets data

No.of teeth | outside diameter | pitch diameter | Hub width |

12 | 3.9in | 3.9in | 1.5in |

Belt data

| ChainType | Plate Width | Working Load(max) | Sideflex Radius(min) | Backflex Radius(min) | Weight | ||||

| mm | inch | N(21º C) | IBF(21º C) | mm | inch | mm | inch | kg/m | |

| S4090-K450 | 114.3 | 4.50 | 2220 | 500 | 457 | 18.00 | 50 | 1.97 | 2.08 |

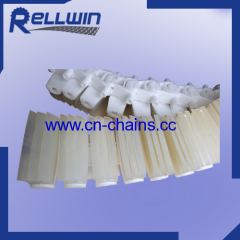

This chainbelt offers a new and unique solution for sideflexing applications in plants with modular conveyor chains. The chainbelt is best suitable for

conveying glass and PET containers(for example pet bottles with petaloid base).

BENEFITS

-high strength and heavy duty flight design.

-standardisation in conveyor design.

-optimum product stability.

"Rellwin Industry Co.,ltd ." with advanced technology, first-class equipment, specializing in the production of manufacturing; This company produces modular conveyor belt more than ten years, product aldehyde

polymer polymer materials, such as modular conveyor belt can be resistant to 140 degrees, designed for tyre, supporting enterprises, for cooling,

transportation, its excellent product performance, quality reached the level of import, lower than similar imported 3-4 times, long service life, etc.

Material: pom, allow adequate airflow through, for cooling products. Mode of transmission: hinge transmission matching: driving wheel, abrasive article

- its length and width can be according to the customer.

modular conveyor chain Rellwin chains are made of plastic modules. Belts are assembled in an interlocked, bricklayed pattern with full-length hinge rods

– an inherently strong design.

strong and reliable

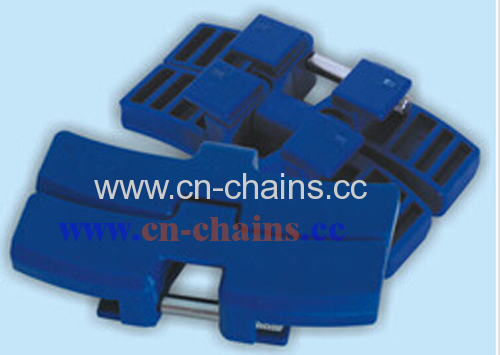

The S4090 chain has increased performance in the following industries/applications:

1. Bakery applications including pan handling and incline/decline box or pan applications.

2. Meat or poultry applications including packaging lines and incline box conveyors.

3. Beverage applications including depalletizers, accumulation tables and incline case conveyors.

4. Can manufacturing applications including palletizers, mass handling and accumulation tables.

5. Corrugated applications including downstacker, corrugator take off, transfer car and WIP storage.

6. Tire applications including wigwag, extruder takeaway and inspection applications.

7. Material handling applications including incline applications, palletizers and packaging lines.

Transportation and daily maintenance of plastic conveyor chains

During storage, the product must be placed into a roll not folded, turning once during placement should be on a quarterly basis

2.Different type, size layers together using the belt should

3.Type conveyor belt, structure, size, number of layers should be a reasonable choice according to the conditions

4.Feed direction along the direction of the tape should be, in order to reduce the impact on the whereabouts of the tape should be taken when the material chute, reducing materials falling distance

Conveyor chains in use should note the following

1.Avoid roller is covered with material, resulting in ineffective rotation to prevent leakage of material between the roller and the tape card, pay attention to the lubrication of moving parts,

2.Avoid starting with a over load

Payment & Shipping Terms | Supply Capacity | ||

Unit Price: | 15.0~85.0 USD | Production Capacity: | 3000 meter/month |

Payment Term: | T/T ,Western Union | Packing: | Carton |

MOQ: | 50Meter | Delivery Date: | 11-17days |

Means of Transport: | Ocean, Air | ||

Why choose the modualr belts?

Modular conveyor belt in an interlocking manner or bricklaying way intertwined by the total length of the pin assembly together, this design improves the

strength of the belt fundamentally. (Rellwin) has extensive experience in the design and application of modular belt fields.

Introduce the specific advantages modular conveyor belt has,compared to other ,in brief sentence.

Rellwin modular conveyor belt bring more valuable solutions than ordinary belts

What are the benefits can the modular bring you?

·By extending the life of the conveyor belt (from a few weeks or a few months to several years extended), significantly reducing the cost of replacement of the

belt

·Save maintenance time and costs: modular design lets you do not need to remove the entire belt to replace the damaged section

·Eliminate deviation and associated costs: drive sprocket tooth forced deviation phenomenon does not occur

·The risk associated with the bond reduced 80% cut-off

·Eliminate all costs associated with the conveyor belt vulcanization, stitching, bonding and surface inspection-related

·Reduce the slope of the yield loss transfer applications: Intralox belt so you can build conveyor Z-shaped configuration, thus eliminating the delivery point will cause product damage, while saving space and reducing the number of drive motors required

·Reduce the risk of contamination due to damage caused by the belt

A modular conveyor belt, which is capable of flexible running and assembly of a plurality of rows of plastic belt modules in the form of modules.Rows

of conveyor belt modules connected by a connecting pin extending along a hinge line with the pin passing through the end of the chain conveyor belt module

as an opening, the opening extending in the longitudinal direction of travel, the adjacent rows of modules the chain ends are staggered,Among them:

Longitudinal direction from the end of conveyor module conveyor extending in the conveying end of the conveyor chain has a slot opening for receiving a

connecting pin conveyor, in each module, the chain conveyor comprises a front end and a rear end of the chain terminal group group wherein one low

chain end groups are in a higher position, and the other in the lower position, the delivery module is assembled and staggered, so that one end of the

module row of high amylose and high chain-end connected rows of adjacent modules, and a module row conveyor connected to the low end of the chain

of another module adjacent rows located at the inside of a turn in the road in turn transport conveyor modules together shrinkage, high chain-end along a

first direction extending in the forward or backward adjacent the upper end of the lower strand of the next module row also extending in the first direction

along a conveying module adjacent to the top by overlapping therewith, the delivery conveyor at the high end of the chain adjacent to the next module in

the row of connecting pins, so that with the turning of the inner edge close to shrink.

Our services

1. Warranty time: 1 year. The conveyor belt / chains / sprockets which supplied by our company could be exchanged when it have quality problems,such as it was broken in installing , the pin run out from chains or the chains parted . But if the user use it in a wrong way, we can not provide any goods for free .

2. Payment: T/T , L/C , Western Union or Paypal .

3. Lead time: 5~15 working days, subject to the order quantity.

4. Shipment: by sea, by air,door to door service for samples transportation.

5. OEM service : we have our own R.D team . If you want to purchase the belt which we have not or you have your own design , we would like to make mold for you for free , only have the condition of requiring continuous orders ,and first order must be more than 60 square meters .

Company and Productsinformationrelated:

Ningbo Rellwin IndustryCo.,ltd