|

Ningbo Rellwin Industry Co.,ltd.

|

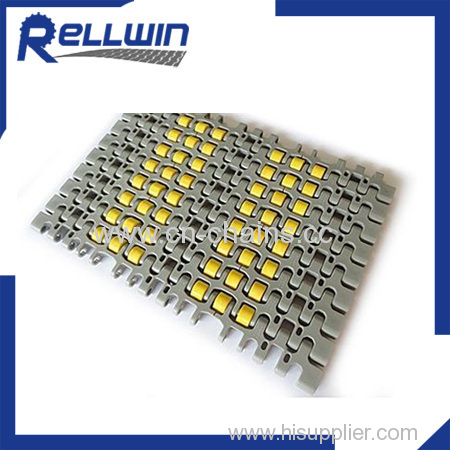

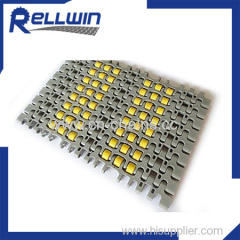

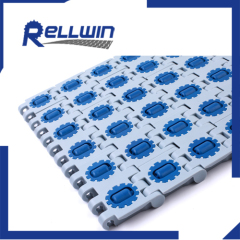

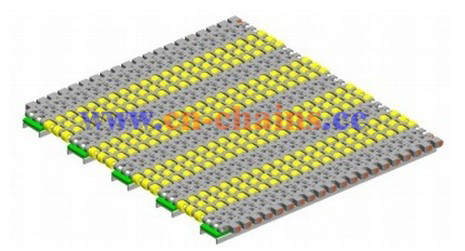

1100C 15.5mm pitch modular plastic conveyor belt transmission

| Price: | 36.0~58.0 USD |

| Payment Terms: | T/T,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.Material:PP/POM

2.Pitch:15.5mm

3.Minimum Width:207mm

4.Open Area:10%

5Weight:8.8kg/m2

6.Side Guard:No

7Temperature range:1℃-100℃

roller top modular plastic conveyor belt

roller top 1100C plastic mudular conveyor belt

| Belt Material | Belt Strength | Temperature | Belt Weight | |||

| Straight | Curve | ℃ (min.) | ℃ (max.) | (K g / M 2 ) | ||

| Kg/M(BW) | ||||||

| Polypropylene | 1580 | ~ | 1 | 100 | 8.8 | |

| Acetal | 1725 | ~ | -40 | 80 | 11.8 | |

| BW – Belt Width | ||||||

Payment & Shipping Terms | Supply Capacity | ||

Unit Price: | 36.0~58.0 USD | Production Capacity: | 1000 square meter/month |

Payment Term: | T/T,Western Union | Packing: | carton |

MOQ: | 10 square Meter | Delivery Date: | 13-18days |

Means of Transport: | Ocean, Air | ||

1100Cplastic modular belt is the leading enterprise in domestic transportation equipment, "Rellwin Industry Co.,ltd ." with advanced technology, first-class equipment, specializing in the production of manufacturing; This company produces modular conveyor belt more than ten years, product aldehyde polymer polymer materials, such as modular conveyor belt can be resistant to 140 degrees, designed for tyre, supporting enterprises, for cooling, transportation, its excellent product performance, quality reached the level of import, lower than similar imported 3-4 times, long service life, etc. Material: pom, allow adequate airflow through, for cooling products. Mode of transmission: hinge transmission matching: driving wheel, abrasive article - its length and width can be according to the customer

BENEFITS

-high strength and heavy duty flight design.

-standardisation in conveyor design.

-optimum product stability.

A modular conveyor belt, which is capable of flexible running and assembly of a plurality of rows of plastic belt modules in the form of modules.Rows of conveyor

belt modules connected by a connecting pin extending along a hinge line with the pin passing through the end of the chain conveyor belt module as an opening,

the opening extending in the longitudinal direction of travel, the adjacent rows of modules the chain ends are staggered,Among them:Longitudinal direction from the end of conveyor module conveyor extending in the conveying end of the conveyor chain has a slot opening for receiving a

connecting pin conveyor, in each module, the chain conveyor comprises a front end and a rear end of the chain terminal group group wherein one low chain end

groups are in a higher position, and the other in the lower position, the delivery module is assembled and staggered, so that one end of the module row of high

amylose and high chain-end connected rows of adjacent modules, and a module row conveyor connected to

the low end of the chain of another module adjacent rows located at the inside of a turn in the road in turn transport conveyor modules together shrinkage, high

chain-end along a first direction extending in the forward or backward adjacent the upper end of the lower strand of

the next module row also extending in

the first direction along a conveying module adjacent to the top by overlapping therewith, the delivery conveyor at the high end of the chain adjacent to the next

module in the row of connecting pins, so that with the turning of the inner edge close to shrink.

A modular conveyor belt, which is capable of flexible running and assembly of a plurality of rows of plastic belt modules in the form of modules.Rows of conveyor belt

modules connected by a connecting pin extending along a hinge line with the pin passing through the end of the chain conveyor belt module as an opening, the

opening extending in the longitudinal direction of travel, the adjacent rows of modules the chain ends are staggered,Among them:Longitudinal direction from the end

of conveyor module conveyor extending in the conveying end of the conveyor chain has a slot opening for receiving a connecting pin conveyor, in each module, the

chain conveyor comprises a front end and a rear end of the chain terminal group group wherein one low chain end groups are in a higher position, and the other in

the lower position, the delivery module is assembled and staggered, so that one end of the module row of high amylose and high chain-end connected rows of

adjacent modules, and a module row conveyor connected to the low end of the chain of another module adjacent rows located at the inside of a turn in the road in

turn transport conveyor modules together shrinkage, high chain-end along a first direction extending in the

forward or backward adjacent the upper end of the lower strand of the next module row also extending in the first direction along a conveying module adjacent to the

top by overlapping therewith, the delivery conveyor at the high end of the chain adjacent to the next module in the row of connecting pins, so that with the turning of

the inner edge close to shrink.

All the conveyor belt must be connected in a ring to use, so joint of conveyor belt directly affect the service life of conveyor belt and if conveyor can run

smooth .Generally,conveyor belt connector commonly used method of mechanical joints, cold thermal curing of adhesive joints, joints, etc. Method of

mechanical joints: generally,refers to the use of belt buckle connectors, the connection method is convenient and easy, economical, but the low efficiency of

the joint, easy to damage, has an impact on conveyor belt service life .PVC and PVG solid woven flame retardant antistatic conveyor belt junction,

class 8, with the following products are generally used this method of joints. Conveyor belt cold bonding connection method: using cold bonding adhesive

for joints. This joint approach than a mechanical joint of high efficiency and more economical, connector should be able to have a better result, but in

practice, due to process conditions is difficult to master and adhesive quality very large impact on joints, so it is not very stable.Conveyor belt vulcanizing

joints: a proved to be ideal for a joint approach to ensure high efficiency of the joint, but also very stable, long life joints and easy to grasp. But technical

troubles, high costs, the connection time and other shortcomings.

Our services

1. Warranty time: 1 year. The conveyor belt / chains / sprockets which supplied by our company could be exchanged when it have quality problems,such as it was broken in installing , the pin run out from chains or the chains parted . But if the user use it in a wrong way, we can not provide any goods for free .

2. Payment: T/T , L/C , Western Union or Paypal .

3. Lead time: 5~15 working days, subject to the order quantity.

4. Shipment: by sea, by air,door to door service for samples transportation.

5. OEM service : we have our own R.D team . If you want to purchase the belt which we have not or you have your own design , we would like to make mold for you for free , only have the condition of requiring continuous orders ,and first order must be more than 60 square meters .

Company and Productsinformationrelated:

Ningbo Rellwin IndustryCo.,ltd