|

Ningbo Rellwin Industry Co.,ltd.

|

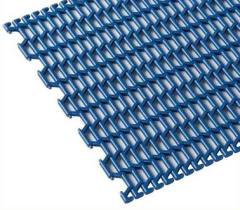

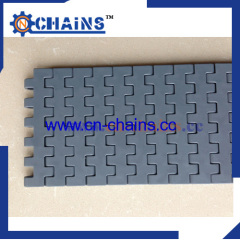

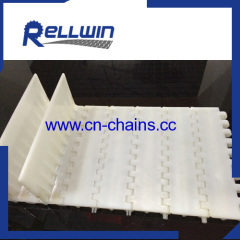

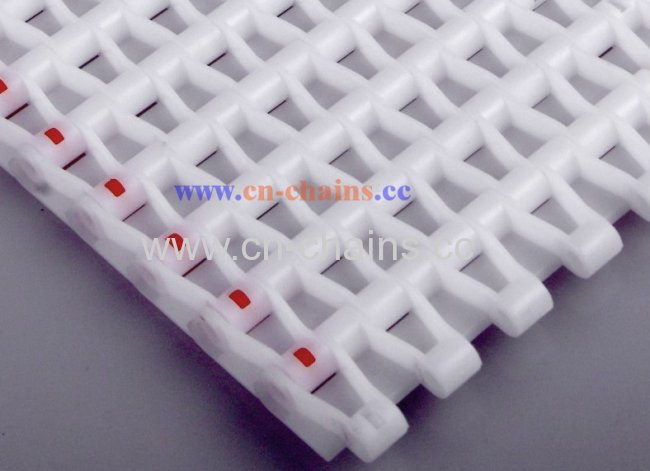

ST 5935 Modular Flat Top conveyor belt 19.05mm pitch

| Price: | 35.0~95.0 USD |

| Payment Terms: | T/T,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.Material:POM / PP

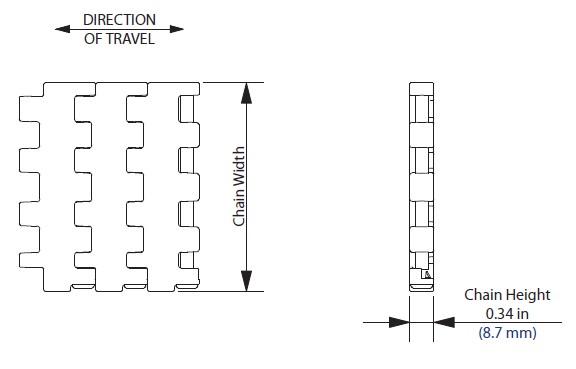

2.pitch:19.1mm

3.Minimum Width:152mm

4.Open Area:0%

5.Flight:Yes

6.thickness:8.7mm

6.Side Guard:Yes

7.Color:Gray and so on

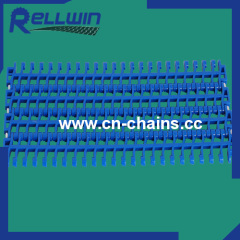

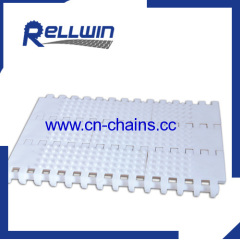

Flat top modular conveyors belt exporter

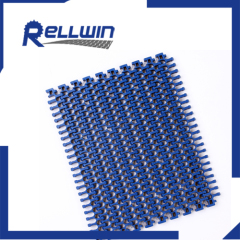

Flat top 5935 plastic straight run conveyor belting(Back)

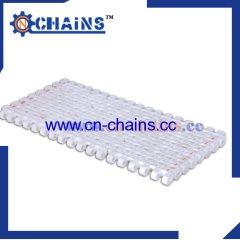

Straight run food grade material plastic modular belt

PU conveyor belt factory

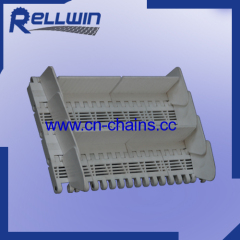

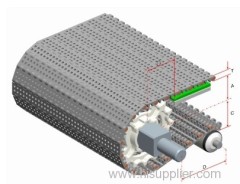

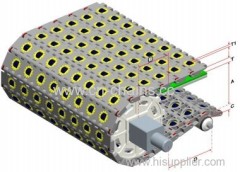

Sprockets for 5935 and 5936

Belt data

| Belt Material | Belt Strength K g /M (B W ) | Temperature | Belt Weight | ||

| Straight | Curve | ℃ (min.) | ℃ (max.) | (K g /M 2) | |

| Polypropylene | 1420 | 1 | 100 | 4.7 | |

| Polyethylene | 1210 | -60 | 60 | 4.9 | |

| Acetal | 2025 | -40 | 80 | 6.5 | |

| Nylon | 1500 | 1 | 180 | 5 | |

| BW – Belt Width | |||||

Sprockets data

Type | Teeth | Pitch Diameter | Outside diameter | Bore

| |||

mm | inch | mm | inch | mm | inch | ||

MS5935-7T | 7 | 43.9 | 1.73 | 42.6 | 1.68 | 16/20 | 0.63/0.79 |

MS5935-10T | 10 | 61.7 | 2.43 | 61.7 | 2.43 | 16/35 | 0.63/1.38 |

MS5935-17T | 17 | 103.7 | 4.08 | 105.0 | 4.13 | 19.1/40 | 0.75/1.57 |

MS5935-24T | 24 | 146.0 | 5.75 | 147.3 | 5.80 | 19.1/40 | 0.75/1.57 |

MS5935-25T | 25 | 152.0 | 5.98 | 153.3 | 6.04 | 19.1/70 | 0.75/2.76 |

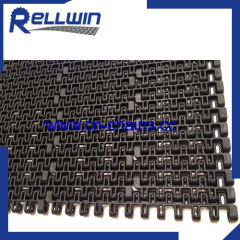

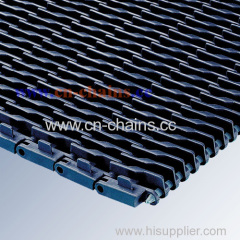

ST5935 Plastic belt is the use of engineering plastics production chain plate assembly made of modular belt with

interlocking brickway interleaved mode or by the total length of the pin assembly together, this design is

fundamentally improve the conveyor belt strength.Flights and side panels can also be interlocked with the

hinge pin has become integral parts of the conveyor belt. Plastic belt has too much forms, assembling flexible,

easy to replace. There are openings in the form, flat, ribs, ball, slip and other forms. Apply to pigs, sheep, chickens,

ducks slaughtered , cutting and processing, puffed food production line, fruit grading, packing lines, fish processing

production line, frozen food production line, battery manufacturing, beverage manufacturing, canning industry, agro-industry, chemical industry , electronics, rubber and plastic manufacturing industry, the cosmetics industry, the general transport operations

Advantage

Precision molding process ensures optimum flatness.

High wear resistance and low friction coefficient

High work load

Transportation and daily maintenance of plastic conveyor belt

1.During storage, the product must be placed into a roll not folded, turning once during placement should be on a quarterly basis

2.Different type, size layers together using the belt should

3.Type conveyor belt, structure, size, number of layers should be a reasonable choice according to the conditions

4.Feed direction along the direction of the tape should be, in order to reduce the impact on the whereabouts of the tape should be taken when the material chute, reducing materials falling distance

Conveyor belts in use should note the following

1.Avoid roller is covered with material, resulting in ineffective rotation to prevent leakage of material between the roller and the tape card, pay attention to the lubrication of moving parts,

2.Avoid starting with a over load

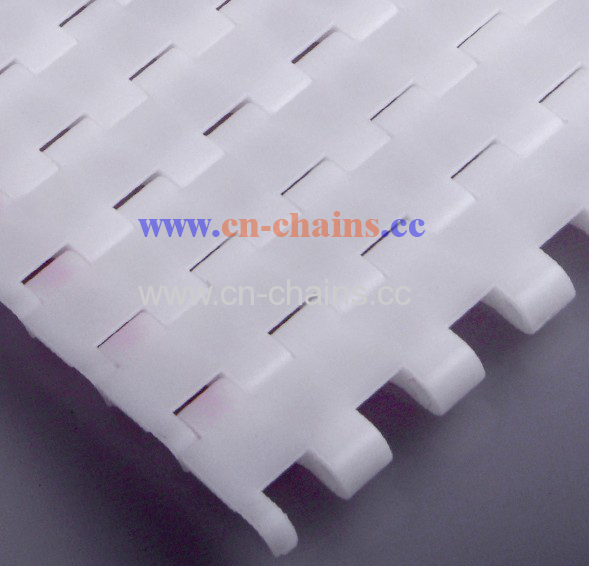

Feature of Plastic modular conveyor belt

Plastic modular conveyor blet using belt injection splicing, and with supporting the drive sprocket, with no deviation drive replacement easier cleaning

characteristics.Plastic mesh belt drive module is stuck in the belt sprocket sprocket grooves are opposite the corresponding drive, so no deviation.Plastic

modular conveyor belt is easier to replace because it is wearing a matching pin assembled, it can be based on partial replacement of damaged parts,

it is unnecessary to replace the whole one , to save a certain amount of expenses.Plastic modular belt is relatively flat and smooth surface, can be

directly rinsed with water and wash with some tools.Plastic materials have arbitrarily chosen to achieve and satisfy the conditions customers, there are

foodgrade plastic belt and high temperature plastic mesh and plastic mesh belt wear and rally.Is a new type of environmentally friendly technology conveyor

ideal supplies. Plastic mesh is also called plastic modular belt belt is the introduction of foreign advanced technology, using molds for injection molding

and then stitched together according to customer demand.

The poultry abattoirs handle a lot of product in their cutting rooms and require a good asepsis.

The Rellwin plastic modular belts enable to convey the poultry meat directly on the belt, as well as inside trays or plastic containers, with the sanitary

guarantee provided by the easy cleaning of our belts.There is no problem in working at low temperatures, so that the product can be frozen directly on our

belts, which involves advantages of lightness, flexibility, and frost easy removal.Our belts do not get any smell or retain any bacterial contamination after their

proper washing, as they are manufactured with plastics whose absorption rate is minimum.

Our services

1. Warranty time: 1 year. The conveyor belt / chains / sprockets which supplied by our company could be exchanged when it have quality problems,such as it was broken in installing , the pin run out from chains or the chains parted . But if the user use it in a wrong way, we can not provide any goods for free .

2. Payment: T/T , L/C , Western Union or Paypal .

3. Lead time: 5~15 working days, subject to the order quantity.

4. Shipment: by sea, by air,door to door service for samples transportation.

5. OEM service : we have our own R.D team . If you want to purchase the belt which we have not or you have your own design , we would like to make mold for you for free , only have the condition of requiring continuous orders ,and first order must be more than 60 square meters .

Company and Productsinformationrelated:

Ningbo Rellwin IndustryCo.,ltd