|

Ningbo Rellwin Industry Co.,ltd.

|

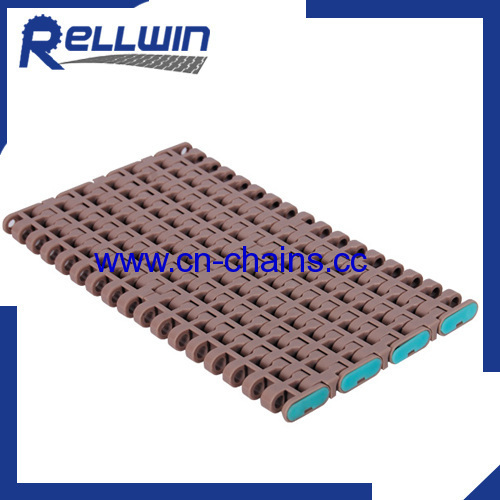

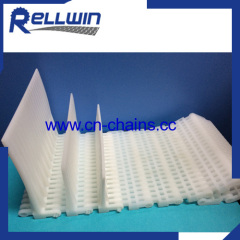

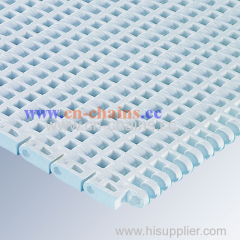

Modular Plastic perforated Belt Conveyor food standard transfer

| Price: | 50.0~110.0 USD |

| Payment Terms: | T/T,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to Basket | Add to My Favorites |

| HiSupplier Escrow |

Product Detail

1.Open area:16 %

2.Belt Pitch:12.7 mm

3.Assembling method:Connected with rods

4.Color:Various color

5.Material:POM,PE,PP.

6Standard:ISO9001:2008

Why Choose Modular Plastic Belting?

Rellwin belts are made of plastic modules. Belts are assembled in an interlocked, bricklayed pattern with full-length hinge rods – an inherently strong design.

Materials

Rellwin standard belt materials:

Polypropylene (PP) is a standard material that's suitable for use in many general applications where chemical resistance to acids, bases, salts, and alcohols may be required. A relatively strong material in normal use, polypropylene exhibits a somewhat brittle quality at low temperatures.

Polyethylene (PE), another lightweight thermoplastic, is characterized by superior fatigue resistance, high impact strength, and flexibility. It is chemically resistant to many acids, bases, and hydrocarbons and can be used at lower temperatures than polypropylene.

Acetal (PA) thermoplastics are considerably stronger than PP and PE. Acetal features a good balance of mechanical, thermal, and chemical properties and a low coefficient of friction.

Specifications

1. Production AndSales Integration

2. Excellent wear resistance

3 . Long operatinglife

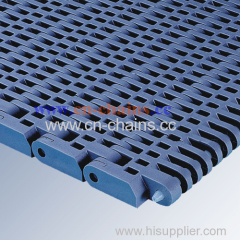

product has high strength, acid, alkali, salt and so on characteristics, wide temperature range, good stickiness, can add baffles, ascending Angle is big, easy to clean, easy maintenance. Can be applied to various conditions of transport. Such as pharmaceutical industry, food industry, packaging industry, daily chemical industry, automobile industry, the logistics industry, entertainment facilities, transmission belt and conveyor equipment.

Basic info:1>Material:POM / PP /PE

2>Weight:6.30kg/m²---POM; 4.30kg/m²---PE; 4.10kg/m²---PP;

3>Color:Various color

4>Pitch:12.7 mm

5>Open area:16%

6>Load capacity:15000 N/M---POM;7500 N/M---PP; 4500N/M---PE

7>Application:Appliesfor

Belttype | BeltMaterial | N/m(21°C) | Lb/ft(21°C) | Belt weight | dry | wet | Backflex radius (min) |

RE-YY-FG500 | POM | 13000 | 890 | 6.0Kg/m2 | +4 to +80°C | +4 to +65°C | 8mm |

| Place of Origin | Color | Type | Certificate | Application | Superiority |

| Ningbo China | grey | Timing Belt | ISO9001:2000 | Bakery/dairy products/packing/cosmetics | Production And Sales Integration |

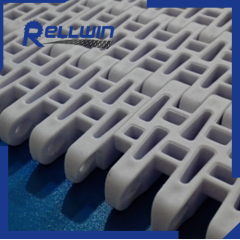

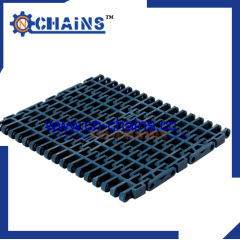

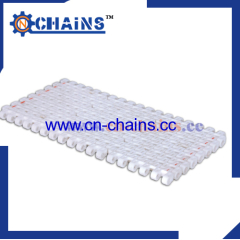

plastic conveyor belt FLUSH GRID 500 wholesales

STRAIGHT CONVEYOR BELT PITCH 12.7MM with grade material

Flush Grid modular plastic belt for conveyor system

..........

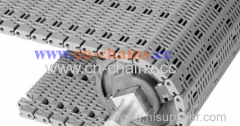

Sprockets for FG500

Belt material:POM(Blue)

PP(White)

PE

Rob material:PP(White) Diameter:5mm

Sprockets data

Type | Teeth | Pitch Diameter | Outside diameter | Bore | |||

mm | inch | mm | inch | mm | inch | ||

CS500-28T | 28 | 113.4 | 4.465 | 113.4 | 4.465 | □40/50 | □1.57/1.97 |

Modular belts are constructed with modules molded from thermoplastic materials connected with soild plastic rods. Except for narrow belts (one complete

module or less in width),all are built with the joints between modules staggered with those of adjacent rows in a "bricklayed" fashion. This structure

can enhance transverse strength and it is easy for maintain.

The total plastic and cleanable design can solve the steel belts easily polluted.Now the cleanable design makes the belts very suitable for food industry

area as well.Also there are be widely used in many other industries,such as container making,pharmaceutical and automotive,lines of battery and so on.

Rellwin company has a widely range of different material and structure belts. The range of Rellwin's modular belts varies from 3/8 inch small pitch

straight running belts to 2inch pitch sideflexing belts,The most commonly used belt styles inclued:

Flat Top:suitable for a wide range of products,when a fully closed belt surface is preferred.

Flush Grid:commonly used in applications where drainage or airflow is desired.

Raised Rib:recommended in applications where product stability over transfers is a concern.

Friction Top:commonly employed on incline conveyors, where the elevation of product changes.Friction Top modular belts can be used up to an angle of 20 degrees,depending on the pack style and material.

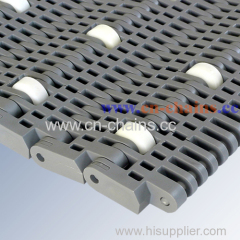

Roller Top:used in a variety of low-pressure accumulation applications.

Perforated Flat Top:used when air flow and water flow are critical but the percentage of belt open area must remain low.

Other,less frequently used belt styles may better fit your special requirements:Open Grid,Nub Top(anti-stick),Cone Top(extra grip).

Transportation and daily maintenance of plastic conveyor belt

During storage, the product must be placed into a roll not folded, turning once during placement should be on a quarterly basis

2.Different type, size layers together using the belt should

3.Type conveyor belt, structure, size, number of layers should be a reasonable choice according to the conditions

4.Feed direction along the direction of the tape should be, in order to reduce the impact on the whereabouts of the tape should be taken when the material chute, reducing materials falling distance

Conveyor belt in use should note the following

1.Avoid roller is covered with material, resulting in ineffective rotation to prevent leakage of material between the roller and the tape card, pay attention to the lubrication of moving parts,

2.Avoid starting with a over load

Feature of Plastic modular conveyor belt

Plastic modular conveyor belt using belt injection splicing, and with supporting the drive sprocket, with no deviation drive replacement easier cleaning characteristics.

Plastic mesh belt drive module is stuck in the belt sprocket sprocket grooves are opposite the corresponding drive, so no deviation.Plastic modular conveyor belt is

easier to replace because it is wearing a matching pin assembled, it can be based on partial replacement of damaged parts, it is unnecessary to replace the whole

one , to save a certain amount of expenses.Plastic modular belt is relatively flat and smooth surface, can be directly rinsed with water and wash with some tools.

Plastic materials have arbitrarily chosen to achieve and satisfy the conditions customers, there are food-grade plastic belt

and high temperature plastic mesh and plastic mesh belt wear and rally.Is a new type of environmentally friendly technology conveyor ideal supplies. Plastic mesh is

also called plastic modular belt belt is the introduction of foreign advanced technology, using molds for injection molding and then stitched together according to

customer demand.

In the preserved food industry, both fish and vegetables pass through different handling and processing stages in which the belt plays a main role. We

are talking about processes like scalding, boiling, vaporization, pasteurization, etc. The belt structure must allow carrying them out in extreme work

conditions without any alteration of its physical-chemical composition, as it could have an influence on those processes.

Once the product has been canned, the cans handling will be also held on our belts, in machines for closing cans, labelling, weighing, product

accumulation, packing, palletizing, depalletizing, or conveying lines to the storeroom.

Our services

1. Warranty time: 1 year. The conveyor belt / chains / sprockets which supplied by our company could be exchanged when it have quality problems,such as it was broken in installing , the pin run out from chains or the chains parted . But if the user use it in a wrong way, we can not provide any goods for free .

2. Payment: T/T , L/C , Western Union or Paypal .

3. Lead time: 5~15 working days, subject to the order quantity.

4. Shipment: by sea, by air,door to door service for samples transportation.

5. OEM service : we have our own R.D team . If you want to purchase the belt which we have not or you have your own design , we would like to make mold for you for free , only have the condition of requiring continuous orders ,and first order must be more than 60 square meters .

Company and Productsinformationrelated:

Ningbo Rellwin IndustryCo.,ltd.