|

Ningbo Rellwin Industry Co.,ltd.

|

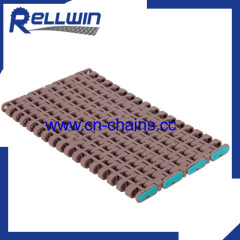

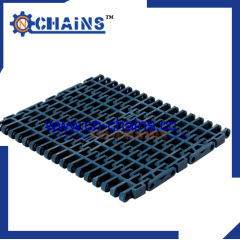

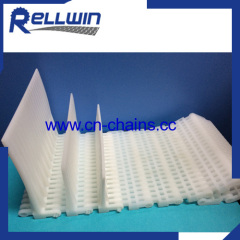

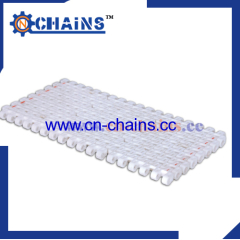

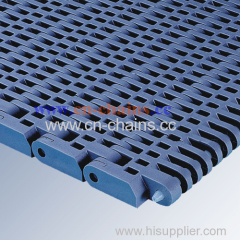

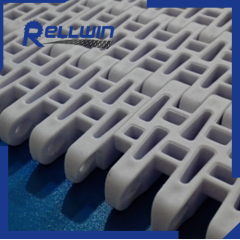

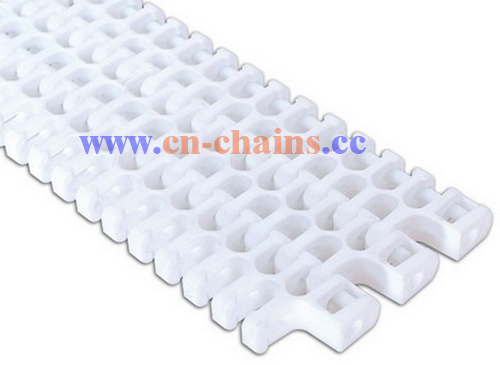

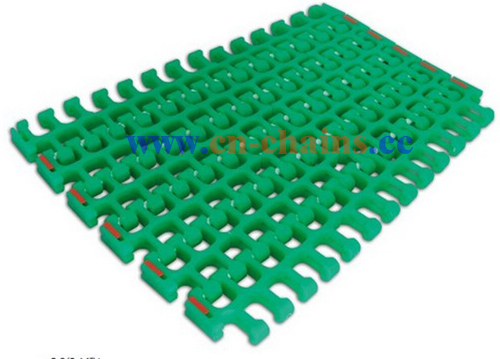

Flush Grid conveyor belt S2400 Radius Grip Top for 25.4mm pitch

| Price: | 60.0~135.0 USD |

| Payment Terms: | T/T,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.Material:Plastic

2.Belt pitch:25.4mm

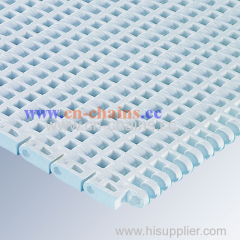

3.Open Area:42%

4.Flights height: 50mm

5.Backflex Radius:50mm

6.Assembling Method:Connected with rods

Flush Grid conveyor belt for conveyor system

25.4mm pitch modular plastic robber top conveyor belt

Radius Flush Grid conveyor belts supplier

Flush Grid S2400 TAB PVC conveyor belts

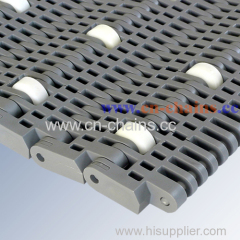

Sprockets for S2400

Sprockets data

Type | Teeth | Pitch Diameter | Outside diameter | Bore(mm)

| |||

mm | inch | mm | inch | mm | inch | ||

FT2400-15T |

15 |

122.16 |

4.8 |

124.0 |

4.9 | 40 | 1.57 |

FT2400-20T | 20 | 162.36 | 6.4 | 163.0 | 6.4 | 40/50 | 1.57/1.97 |

| Belt type | Belt material | Working load(max.) | Belt weight | Temperature range | Backflex radius | ||

| (min.) | |||||||

| N/m(21°C) | Lb/ft(21°C) | Kg/m² | Dry | Wet | mm | ||

| TR2400 | POM | 24800 | 1100 | 10.8 | -40 to +80°C | -40 to +65°C | 50 |

| PP | 17500 | 780 | 7.00 | +5 to +104°C | +5 to +104°C | ||

Payment & Shipping Terms | Supply Capacity | ||

Unit Price: | 60.0~135.0 USD | Production Capacity: | 1000 square meter/month |

Payment Term: | T/T,Western Union | Packing: | carton |

MOQ: | 15square Meter | Delivery Date: | 12-16days |

Means of Transport: | Ocean, Air | ||

Flush Grid top modular conveyor belt

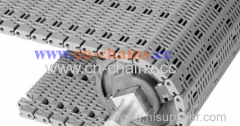

Rellwin belts are made of plastic modules. Belts are assembled in an interlocked, bricklayed pattern with full-length hinge rods – an inherently

strong design.

strong and reliable

The Flush Grid S2400 belt has increased performance in the following industries/applications:

1. Bakery applications including pan handling and incline/decline box or pan applications.

2. Meat or poultry applications including packaging lines and incline box conveyors.

3. Beverage applications including depalletizers, accumulation tables and incline case conveyors.

4. Can manufacturing applications including palletizers, mass handling and accumulation tables.

5. Corrugated applications including downstacker, corrugator take off, transfer car and WIP storage.

6. Tire applications including wigwag, extruder takeaway and inspection applications.

7. Material handling applications including incline applications, palletizers and packaging lines.

Why choose the modualr belts?

Modular conveyor belt in an interlocking manner or bricklaying way intertwined by the total length of the pin assembly together, this design improves the

strength of the belt fundamentally. (Rellwin) has extensive experience in the design and application of modular belt fields.

Introduce the specific advantages modular conveyor belt has,compared to other ,in brief sentence.

Rellwin modular conveyor belt bring more valuable solutions than ordinary belts

What are the benefits can the modular bring you?

·By extending the life of the conveyor belt (from a few weeks or a few months to several years extended), significantly reducing the cost of replacement of

the belt

·Save maintenance time and costs: modular design lets you do not need to remove the entire belt to replace the damaged section

·Eliminate deviation and associated costs: drive sprocket tooth forced deviation phenomenon does not occur

·The risk associated with the bond reduced

80% cut-off

·Eliminate all costs associated with the conveyor belt vulcanization, stitching, bonding and surface inspection-related

·Reduce the slope of the yield loss transfer applications: Intralox belt so you can build conveyor Z-shaped configuration, thus eliminating

the delivery point will cause product damage, while saving space and reducing the number of drive motors required

·Reduce the risk of contamination due to damage caused by the belt

Rellwin modular conveyor belt bring more valuable solutions than metallic belts.

What are the benefits can the modular bring you?

·By extending the life of the conveyor belt (from a few weeks or a few months to several years extended), significantly reducing the cost of replacement of the belt

·Save maintenance time and costs: modular design lets you do not need to remove the entire belt to replace the damaged section

·Reduce the risk of contamination due to damage caused by the belt

The current methods for producing wine are far away from those used by our ancestors. Nowadays, derived from complex and costly technical studies,

meticulous systems of detailed care are carried out regarding the soil, the plant, the fruit, and, of course, its transformation in wine in order to

obtain the best quality.

But for all this, it is essential a conveying and handling aseptic system for cooling the grapes, selecting them, and carrying them to the destemmer with

the care and asepsis required by the most demanding quality control.Our modular belts have been carrying out this task in this selective industry

successfully for some years, so that they are installed in the most famous wineries.

Our services

1. Warranty time: 1 year. The conveyor belt / chains / sprockets which supplied by our company could be exchanged when it have quality problems,such as it was broken in installing , the pin run out from chains or the chains parted . But if the user use it in a wrong way, we can not provide any goods for free .

2. Payment: T/T , L/C , Western Union or Paypal .

3. Lead time: 5~15 working days, subject to the order quantity.

4. Shipment: by sea, by air,door to door service for samples transportation.

5. OEM service : we have our own R.D team . If you want to purchase the belt which we have not or you have your own design , we would like to make mold for you for free , only have the condition of requiring continuous orders ,and first order must be more than 60 square meters .

Company and Productsinformationrelated:

Ningbo Rellwin IndustryCo.,ltd.